class 100 clean room is defined as

Room with a defined concentration of airborne particles designed and used in a way that the number of particles introduced into the room or originating and being deposited in the room is as small as possible and in which other cleanliness-relevant parameters such as temperature humidity and pressure can be controlled as required VDI. Axenics operates a Class 100 cleanroom at its facility in Tyngsboro MA.

Clean Room Classification In Pharmaceutical Production Production

Currently there is a lot of the latter at Axenics with the current demand for clean room welding.

. Here the level of pollution is the number of particles per cubic meter at a specified particle size. Not more than 100 per cubic of 05 im and larger in size. Therefore when an inspection needs to.

The internal components of a hard drive have very little tolerance for dust contamination. We built our cleanroom in 1996 inside our existing fab shop. It is a vital component for any company who is a serious provider of data recovery services.

ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled and have a maximum particle count of 100000 particles 05 um per cubic foot of interior air. A class 100 cleanroom has 100 particles per cubic foot. Clean room has HEPA filters to clean the incoming area.

By comparison your typical office space has between 500000 and 1 million particles per cubic foot. A class 100 cleanroom to a class 10000 cleanroom refers to this kind of working environment. What is a cleanroom.

To meet requirements of a clean room as defined by Federal Standard 209E and newer ISO Standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class. Maximum permitted number of particlesm3 equal to or above. All About Class 100 Clean Room.

300 per cubic foot. An ISO 6 clean room Class 1000 cleanroom is a soft- or hard-sided wall manufactured structure that utilizes HEPA filtration systems to maintain air cleanliness levels of a maximum of 1000 particles 05 µm per cubic meter of inside air. They are required to have HEPA filtration coverage over 4-5 of the area and provide a minimum of 20 air exchanges per hour with air flow rates of 4-8 CFM per square foot.

Contaminants like airborne dust and other particles can cause failure and waste resources. Definition of Clean Room Classes Definition of the different Clean Room Classes Former FED STD 209 E - overview cancelled Class Name 01 micron 02 micron 03 micron 05 micron 5 micron 1 35 7 3 1 10 350 75 30 10 100 750 300 100 1000 1000 7 10000 10000 70 100000 100000 700 Fig. Not more than 120 per cubic foot of 05 im and larger in size.

The maximum allowable particles for particles for a Class 10 Cleanroom are below. Class 100 Cleanroom is the third classification type of the FED-STD-209 classification standard the Class 100 Cleanroom corresponds to the Class 5 Cleanroom of the ISO standard. 100 per cubic foot.

Cleanrooms come in different classes from class 100 to 100000. The maximum allowable particles for particles for a Class 100 Cleanroom are below. A clean room doesnt mean you just vacuumed and dusted or picked up your old socks off the floor.

Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. As the highlighted portions of the chart indicate our cleanroom is Class 100- and Class 1000-rated ISO 5 and ISO 6. In the component manufacturing world theres dirty work and clean work.

Inside the cleanroom the team of expert technicians performs high-purity welding and orbital. Temperature humidity and pressure are controlled as necessary ISO-1 p. A cleanroom is an environment where airborn particulates are controlled through an exchange of highly filtered air using a high efficiency particulate air HEPA filtering system and through minimization of activities that generate particles.

The Federal Standard 209 FS 209E equivalent for these ISO classes are Class 10000 and Class 100 000. What is a class 100 cleanroom. Clean Room A room in which the concentration of airborne particles is controlled to meet a specified airborne particulate Cleanliness Class.

Grade C and D areas graded C and D are used for performing less critical tasks that are carried out during less critical stages in the manufacturing process. Up to 4 cash back been laundered in a class 100 cleanroom using ultra-filtered water of 045 micron purity and HEPA-filtered air during moisture removal. Class 100000 cleanrooms or ISO level 9 rooms also exist.

A Class 100 Clean Room is an environment where the level of contamination caused by dust particles chemical vapours airborne is controlled or at quite a low level. 75 per cubic foot. Class 1000 defined same where there should not be more than 1000 particles and so on respectively.

Cleanroom for microelectronics manufacturing with fan filter units installed in the ceiling grid. The most common ISO clean room classes are ISO 7 and ISO 8. Each Cleanliness Class defined is also assigned a microbial level for air surface and personnel gear.

Air cleanliness in our cleanroom. The old Federal Standard 209E FS 209E includes these clean room classes. In addition the concentration of microorganisms in the environment is monitored.

Class 1000 cleanroom filtration system must provide filter coverage of 20-30 and a minimum of. A cleanroom or clean room is an engineered space which maintains a very low concentration of airborne particulates. 750 per cubic foot.

350 per cubic foot. 30 per cubic foot. Class 10 Cleanroom is the second classification type of the FED-STD-209 classification standard the Class 10 Cleanroom corresponds to the Class 4 Cleanroom of the ISO standard.

A clean room is commonly heard with regards to data recovery. Cleaning solvents can be Di Water a blend of Di Water and Isopropyl alcohol blends cleanroom compatible cleaners and. A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic.

Not more than 100 per cubic foot of 05 im and larger in size. Of volume requires 6 FFUs. Class 100 area is defined as area where there should not be more than 100 particles of 05 micron per cubic foot of air.

HEPA means high efficiency particulate air. Modern manufacturing processes and scientific research often require specific very clean environmental conditions. A room in which the concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction generation and retention of particles inside the room and in which other relevant parameters eg.

Class 100 clean room is defined as a room in which theparticle count in the air is. To meet the same standard using the high-end air change recommendation 480hour requires 12 FFUs. It is well isolated well-controlled from contamination and actively cleansed.

Even if its classified as the dirtiest class the ISO 9 clean room environment is cleaner than a regular room. The space is about 40 feet by 40 feet and is separated into three main areas. The airborne particulate classification for these grades is given in the following table.

Generally speaking a clean room is an enclosed room that has equipment which controls the amount of particulate matter in the air by using air pressure and filters. First a small gowning room was built at the entry.

Clean Room Classifications Iso Standards Quotes 48 Hours

Cleanroom Cleaning And Gowning Protocol Guide Iso 14644

Three Posts Rhinebeck 75 Recessed Arm Sofa Fabric Gray 100 Linen Modern Furniture Living Room Living Room Style Sofa

Pin Ot Polzovatelya Inna Voinich Na Doske Future House Decor Dizajnerskie Gostinye Nebolshie Gostinye Gostinaya V Serom Cvete

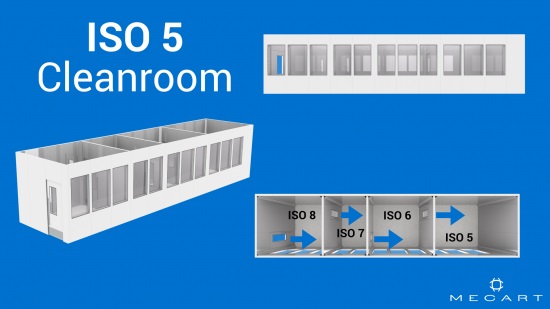

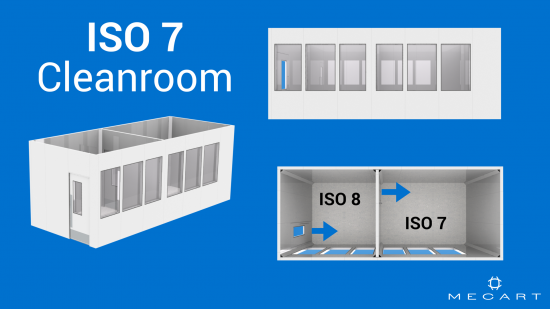

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

What Is Iso 8 Cleanroom Classification

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classification In Pharmaceutical Production Production

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

Clean Room Classification In Pharmaceutical Production Production

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

Iso 7 Clean Room Manufacturer Class 10000 Clean Rooms

Sculptural Home With Clean Lines In Madrid Living Room Design Modern Living Room Designs House Interior